Some links in this article are affiliate links. As an Amazon Associate I earn from qualifying purchases. This helps support the site at no extra cost to you.

Quick Verdict

3D printing has matured a lot in 2025 — faster, smarter, and more user-friendly machines now ship with robust software, AI monitoring, and plug-and-play workflows. From prosumer speed demons to reliable workhorse printers and high-detail resin rigs, here are the best 5 3D printers in 2025, ranked by performance, features, and everyday usability.

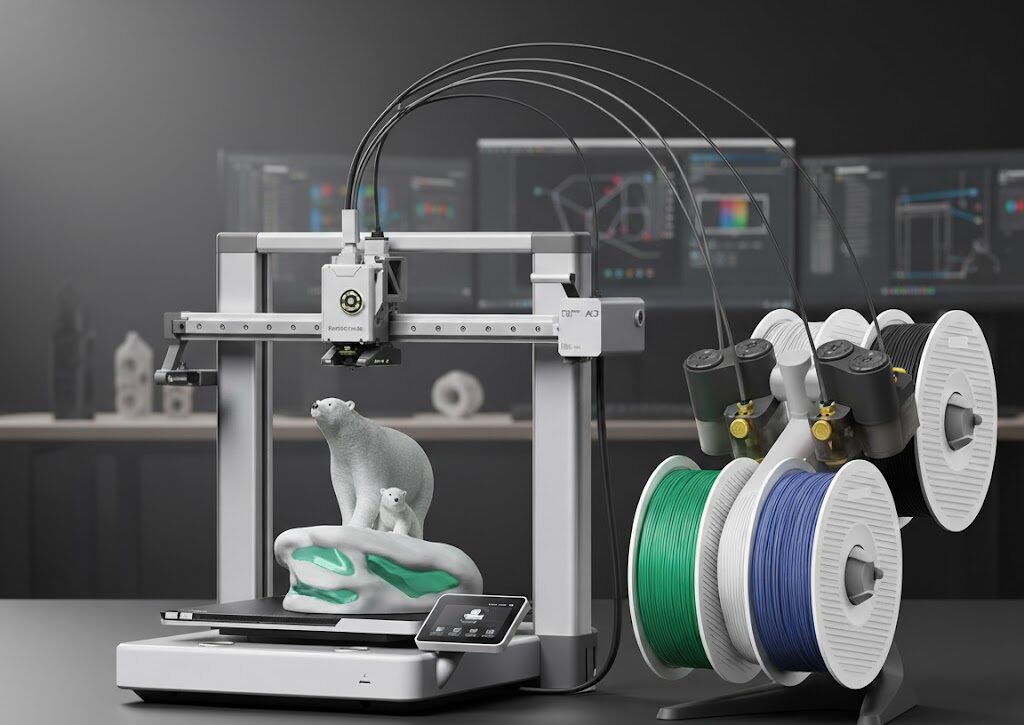

Bambu Lab A1 Combo

The Bambu Lab A1 Combo gives you near-industrial convenience in a desktop printer: full-auto calibration, active flow-rate compensation, quiet motors, and easy multi-color printing via the AMS lite. It’s fast, reliable, and remarkably hands-off for hobbyists, small shops, and pros who want consistent results without constant fiddling. If you want an automated, high-quality FDM experience that “just works” most of the time, this is one of the best value-packed printers in 2025.

Key Specs

Build volume: 256 × 256 × 256 mm.

Multi-color support: AMS lite (included in Combo).

Auto systems: Full-auto calibration + active flow-rate compensation.

Noise: Active motor noise cancelling — advertised quiet operation (~≤48 dB in practical use).

Extras: 1-clip quick-swap nozzle, robust motion control, broad filament support via AMS lite.

Why you might buy it

- Plug-and-print convenience: The full-auto calibration system dramatically reduces setup frustration and failed first prints — great for beginners and pros who value uptime.

- Multi-color without complexity: The AMS lite lets you run multi-filament jobs (color changes, soluble supports) without wiring a complex MMU rig. Perfect for expressive prints and functional parts.

- Reliable, high-speed output: Advanced motion control, nozzle pressure sensing and flow compensation deliver clean surfaces at speed — you get throughput without sacrificing detail.

- Friendly noise profile & workflow: Active motor noise cancelling plus automation makes it suitable for home workshops and shared spaces.

Pros

- Truly automated calibration and compensation reduce trial-and-error.

- AMS lite adds drop-in multi-color capability.

- Strong community, frequent firmware/feature updates, and ecosystem tools.

- Quiet for a desktop high-speed machine; useful in living/work spaces.

Cons

- AMS lite compatibility and some filament restrictions (e.g., wet PVA) — check supported filaments.

- Advanced automation can mask failure modes; some power users prefer manual control for niche workflows.

- Recent company software/firmware policy discussions raise privacy and “walled garden” concerns for a few users — worth reading before buying.

FlashForge Adventurer 5M

The FlashForge Adventurer 5M is a fast, user-friendly CoreXY desktop 3D printer that balances speed, automation, and approachable maintenance for makers and small shops. It pairs a compact 220×220×220 mm build volume with quick-swap nozzles, one-click auto-leveling, and high acceleration for rapid prototyping — making it a standout choice if you want reliable results without endless tinkering.

Key Specs

Build volume: 220 × 220 × 220 mm.

Motion system: CoreXY — max travel up to 600 mm/s and acceleration up to 20,000 mm/s² (high-speed capable).

Hotend / temps: Rapid-heat direct-drive hotend (up to ~280 °C), quick-swap nozzles (0.25/0.4/0.6/0.8 mm options).

Bed & leveling: PEI-coated removable bed + full one-click automatic leveling.

Interface & connectivity: 4.3″ touch screen, Wi-Fi, USB stick, Ethernet, cloud printing.

Why you might buy it

- Speed without sacrificing quality: CoreXY mechanics and aggressive acceleration let you prototype much faster than conventional Cartesian hobby printers, which shortens iteration time.

- Low-effort setup & maintenance: One-click auto-leveling and quick-swap nozzles make it approachable for newcomers while saving time for experienced users.

- Versatile materials: The heated bed and higher nozzle temps support PLA, PETG, and many engineering filaments (enclosure available separately for more temperature-sensitive materials).

Pros

- Very fast motion system for rapid prints.

- User-friendly automation (auto leveling, quick nozzles).

- Compact footprint with full connectivity options (Wi-Fi / USB / Ethernet).

- Good out-of-box finish for hobbyists and small production runs.

Cons

- Real-world top speeds are lower than the headline numbers when print quality is prioritized.

- For high-temperature filaments (Nylon, some industrial grades) you’ll likely need the optional enclosure and careful material handling.

- Some advanced users prefer the finer control and larger ecosystems offered by other high-end brands.

Creality Ender 3 V3 SE

The Creality Ender 3 V3 SE is an impressive budget-friendly 3D printer that blends speed, precision, and ease of use — perfect for beginners and hobbyists who want reliable results without constant tinkering. With its automatic bed leveling, direct drive extruder, and sturdy build, it delivers consistent, high-quality prints out of the box. It’s one of the most approachable and dependable printers in Creality’s lineup, ideal for both newcomers and makers looking for a reliable daily workhorse.

Key Specs

Build volume: 220 × 220 × 250 mm

Print speed: Up to 250 mm/s

Leveling: Automatic bed leveling with strain sensor + Z offset calibration

Extruder: Direct drive “Sprite” extruder (compatible with flexible filaments)

Nozzle temp: Up to 260°C

Bed temp: Up to 100°C (fast heating PEI-coated spring steel build plate)

Frame: Sturdy dual Z-axis design for improved stability

Interface: 4.3″ color display with intuitive UI

Assembly: Semi-assembled — ready in about 20 minutes

Why you might buy it

- Beginner-friendly automation: The auto-leveling and Z-offset calibration save time and frustration, giving you perfect first layers every time.

- Smooth and quiet printing: Thanks to silent stepper drivers and stable dual Z-axis motion, it prints quietly with minimal vibration.

- Fast and reliable performance: The Sprite direct drive ensures smooth extrusion for PLA, PETG, and TPU — even flexible materials print effortlessly.

- Excellent value: Delivers pro-level results at an entry-level price, with a design that’s easy to upgrade later.

Pros

- Automatic bed leveling for hassle-free setup

- Strong frame and dual Z-axis for consistent layer alignment

- Fast, quiet, and smooth printing experience

- Direct drive extruder works well with a variety of materials

- Great value for money and beginner accessibility

Cons

- Limited to small-to-medium print sizes

- No enclosure, so high-temp materials like ABS may need extra care

- Screen interface, while clear, isn’t touchscreen

ANYCUBIC Photon Mono M7 Pro

The ANYCUBIC Photon Mono M7 Pro is a standout resin 3D printer for 2024–2025: ultra-high 14K resolution, rapid curing with LightTurbo 3.0, and helpful automation (auto-leveling, auto resin refill/withdrawal, AI exposure tweaks). It’s built for creators who want razor-fine detail and smoother, faster prints without spending hours on manual setup. Expect professional-grade miniatures, jewelry prototypes, and highly detailed parts straight from a desktop machine.

Key Specs

Screen / resolution: 10.1″ monochrome LCD, 14K (≈13,312 × 5,120 pixels), XY pixel ~16.8 × 24.8 µm

Build volume: ~223 × 126 × 230 mm (8.8 × 5.0 × 9.1 in)

Max print speed: up to ~130 mm/h (standard resin), ~170 mm/h (high-speed resin)

Optics: LightTurbo 3.0 (COB + Fresnel lens) for uniform exposure

Automation: One-click auto-leveling, auto resin refill & withdrawal, controlled resin heating

Workflow: App/Wi-Fi support, auto exposure/AI compensation, removable vat & laser-etched plate

Why you might buy it

- You want extreme detail — the 14K LCD unlocks very fine features and small holes that lower-res machines can’t reproduce.

- You want less babysitting — auto-leveling and resin pump features cut down manual fiddling and failed first layers.

- You need speed without huge sacrifices — LightTurbo optics and high-speed resin support significantly shorten print times on appropriate models.

- You want a desktop professional tool that’s approachable for advanced hobbyists and small shops.

Pros

- Exceptional print detail and surface finish thanks to 14K resolution.

- Fast cure rates with LightTurbo 3.0, lowering print times on many models.

- Useful automation (auto leveling, resin pump refill/withdraw) improves success rate.

- Large enough build area for many multi-part jobs and taller models.

- Robust feature set aimed at both hobbyists and pros.

Cons

- Auto-refill can be finicky with non-airtight bottles or poorly sealed caps; setup attention required.

- Resin printing smells — good ventilation and PPE are mandatory.

- App/Wi-Fi workflows add convenience but can be clunky for some users; USB/local options remain necessary.

- Higher-res printing exposes model and slicer weaknesses — great results require good source models and tuned slicing.

ELEGOO Mercury Wash & Cure

The ELEGOO Mercury wash & cure station with turntable is a tidy, user-friendly all-in-one finishing station for resin 3D prints. It streamlines the post-print workflow—wash, dry, and 360° UV cure—so hobbyists and small studios can go from sticky prints to strong, fully cured parts with less mess and fewer steps. It’s a great value if you want consistent curing and easier cleanup without juggling multiple tools.

Key Specs

Function: Combined wash + UV cure station with powered turntable for even exposure.

Wash mode: Agitation/rotation for cleaning prints in isopropyl alcohol (IPA) or dedicated wash fluid.

Cure mode: 360° turntable plus ring of UV LEDs for even curing (typical LED wavelengths around 365–405 nm).

Controls: Timer modes for wash and cure cycles; simple button/touch controls.

Capacity: Sized for typical desktop resin parts and miniatures (fits most prints from hobby printers).

Build & safety: Enclosed lid, removable basket/holder for easy cleaning, and auto shut-off when lid opens.

Why you might buy it

- One-box workflow: Combines both the washing and curing steps in a compact unit so you don’t need separate machines or awkward manual cures.

- More consistent results: Turntable + ring LEDs give more even UV exposure than single-sided cure lamps, reducing warping and sticky spots.

- Cleaner, faster finishing: Motorized washing cuts the time and scrubbing needed compared with hand-rinsing, and a dedicated curing chamber removes tack in minutes.

- Beginner friendly: Simple timers and removable baskets make the unit approachable for newbies while still helpful for pros doing repeatable jobs.

Pros

- Simplifies post-processing into a single, compact device.

- Even, 360° UV curing for better mechanical properties and surface finish.

- Reduces manual handling and mess (less scrubbing, fewer IPA spills).

- Removable tray/basket makes cleaning and part handling straightforward.

- Safety features (enclosed curing, lid interlock) minimize accidental UV exposure.

Cons

- You still need IPA or wash fluid and proper ventilation — resin cleaning produces fumes.

- Capacity is limited to desktop print sizes; very large prints may not fit.

- UV curing generates heat and strong light — follow safety guidelines.

- Replacement parts (turntable, basket) and maintenance add running costs over time.

Final verdict

Choosing the right 3D printing gear in 2025 depends on what you want to make and how hands-on you want to be.

The Bambu Lab A1 Combo earns the crown as the best overall 3D printer package — its full-auto calibration, active flow compensation and AMS lite multi-color support deliver pro-level results with minimal fuss, making it ideal for makers and small studios who want fast, reliable output. If you need speedy prototyping and high throughput on a budget, the FlashForge Adventurer 5M is the pick: CoreXY motion and quick-swap nozzles accelerate iteration without a steep learning curve. For beginners and value seekers, the Creality Ender 3 V3 SE is the smartest buy — a dependable, user-friendly FDM workhorse that balances price, performance and upgradeability.

When ultra-fine detail is the priority, the ANYCUBIC Photon Mono M7 Pro stands out as the best resin printer — 14K resolution, LightTurbo optics, and smart automation produce jewelry-grade miniatures and precision prototypes. And don’t forget finishing: the ELEGOO Mercury Wash & Cure is the top choice for post-processing, combining motorized washing and 360° UV curing to turn sticky resin prints into fully cured, durable parts quickly and cleanly.

In short, there’s no single “perfect” machine — but this lineup covers every core need in modern desktop fabrication: all-around automation, rapid prototyping, budget reliability, ultra-detail resin work, and efficient finishing. Pick the one that matches your workflow and you’ll spend more time making and less time troubleshooting.